Home > Ductile iron pipes & fittings

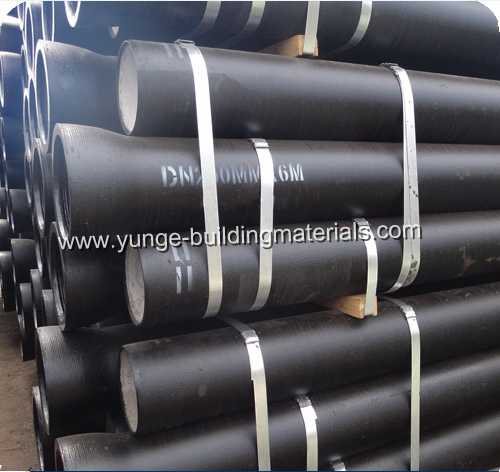

C25, C30, C40 K9 Ductile Iron pipe

- Standard:ISO2531/EN545/EN598

- Application:Potable/sewage water pipeline

- Diameter:DN 80-2600 mm

- Length:6m for bulk shipment and 5.7m for container shipment

- Product description:

C25, C30, C40 K9 Ductile Iron pipe

Quick Details

Standard:ISO2531/EN545/EN598

Application:Potable/sewage water pipeline

Diameter:DN 80-2600 mm

Pipe Wall Thickness:K9, C40, C30, C25

Length: in general, the pipe length is 6m for bulk shipment and 5.7m for container shipment.

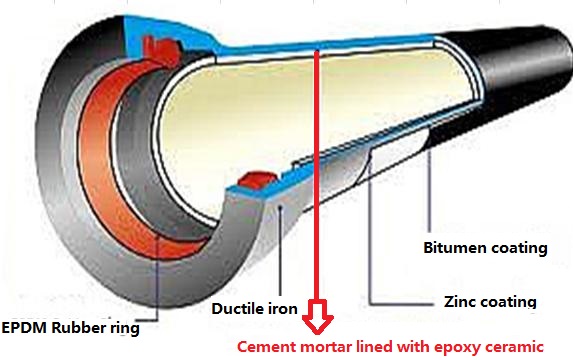

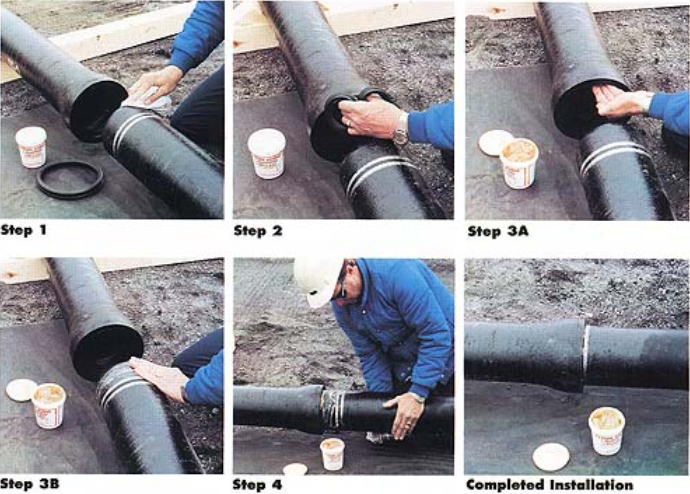

Joint Type:push-on joint(Tyton joint), K type joint, flange joint

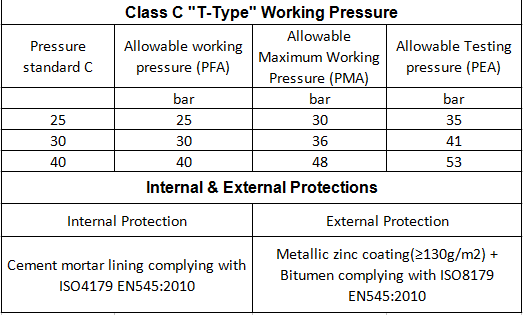

External Coating:Zinc + bitumen painting,fusion bonded epoxy coating

Zinc coating: at least 130g/m2 as per ISO 8179

Bitumen painting: at least 70um as per ISO 8179

Internal coating:Cement mortar lining as per ISO4179

Gasket:NBR rubber, natural rubber, SBR rubber or EPDM rubber ring as per ISO4633

Features:High strength, lighter than gray iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life time

Chemical composition: (%):

a) C: 3.5 - 4.0

b) Si: 1.9 - 2.6

c) Mn:0.15 - 0.45

c) P: <0.06

d) S: <0.02

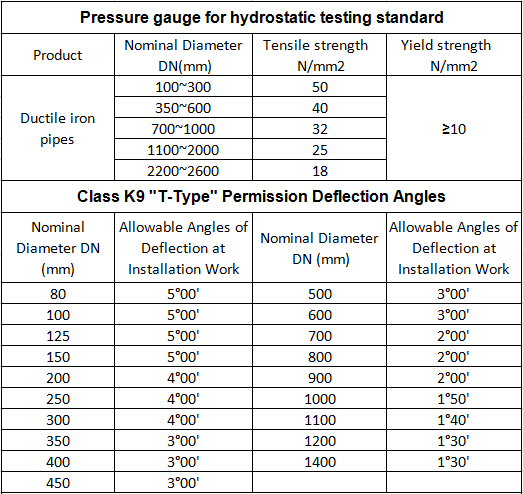

Mechanical properties:

a) Tensile strength: ≥420MPa

b) Yield strength: ≥300Mpa

c) Hardness: ≤230HB

d) Elongation%: DN80 - 1000 ≥10 DN1200 - 2200 ≥7

Process and testing:

a) Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)

b) Casting (Visual check and weight check)

c) Heat treatment (Micro structure)

d) Hydrostatic test (Pressure test)

e) Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)

f) Zinc spraying (Thickness testing)

g) Lining and coating (100% visual check, thickness testing randomly)

h)Marking and packing (100% visual check)Packaging Details:bundled with steel belts or in bulk

Packaging Details:bundled with steel belts or in bulk

Lead Time:According to the quantity,20-30 days after receiving the deposit

Specification:

| DN mm | OD. | Sokect | K9 | K10 | ||||

| Thickness mm | Weight for 1 meter KG | Weight for1pcs=6m KG | Thickness mm | Weight for 1 meter KG | Weight for 1pcs=6m KG | |||

| 100 | 118 | 4.3 | 6 | 14.9 | 95 | 6 | 17.4 | 110 |

| 150 | 170 | 7.1 | 6 | 21.8 | 144 | 6.5 | 24.5 | 156 |

| 200 | 222 | 10.3 | 6.3 | 30.1 | 194 | 7 | 33.3 | 210 |

| 250 | 274 | 14.2 | 6.8 | 40.2 | 255 | 7.5 | 44.3 | 280 |

| 300 | 326 | 18.6 | 7.2 | 50.8 | 323 | 8 | 56.3 | 356 |

| 400 | 429 | 29.3 | 8.1 | 75.5 | 482 | 9 | 83.7 | 532 |

| 500 | 532 | 42.8 | 9 | 104.3 | 669 | 10 | 115.6 | 736 |

| 600 | 635 | 59.3 | 9.9 | 137.3 | 883 | 11 | 152 | 971 |

| 700 | 738 | 79.1 | 10.8 | 173.9 | 1123 | 12 | 193 | 1237 |

| 800 | 842 | 102.6 | 11.7 | 215.2 | 1394 | 13 | 238.7 | 1535 |

| 900 | 945 | 129.9 | 12.6 | 260.9 | 1691 | 14 | 288.7 | 1862 |

| 1000 | 1048 | 161.3 | 13.5 | 309.3 | 2017 | 15 | 342.2 | 2221 |

Workshops:

Test & Inspection

Application

Installation

Categories

Contact

CONTACT USContact:Vivian Yue

Phone:

Email:yungetrading@gmail.com

Add:Room 2006,Block B,Tianrun complex building,Dongfeng East street,Weifang,Shandong Province, China

Pipes&fittings

Pipes&fittings